The Pros and Cons of Optical Dissolved Oxygen Sensors

If you’re trying to keep fish alive and healthy, dissolved oxygen is the most important measurement for water quality. Accurately measuring dissolved oxygen can have major implications for fish health in aquaculture ponds and nets, reservoirs, and other water bodies.

For accuracy and ease, dissolved oxygen sensors are the clear favorite over other measurement methods, but not all sensors are created equal.

There is a sensor to fit every need but looking at optical dissolved oxygen sensors in a little more detail is worthwhile since they are the longest-lasting, most accurate and convenient option out there. Such convenience can come at an elevated cost, though. Take a look at the pros and cons of optical dissolved oxygen sensors to confirm they’re the right choice for you.

Pro: The most convenient dissolved oxygen monitoring available

If you need a dissolved oxygen sensor that you can set and forget, an optical option is likely the one for you.

In head to head matchups with electrochemical sensors, optical sensors were more accurate and reliable over the long term. In a handbook for dissolved oxygen monitoring, the Wisconsin Department of Natural Resources said optical sensors could be deployed for the entirety of the testing season. That means fewer maintenance trips and less hassle with faulty equipment.

Biofouling is the most often discussed source of disruption for dissolved oxygen monitoring, but a relatively simple wiper can be added to optical sensors, keeping them clear of algae while taking accurate measurements.

Pro: DO monitoring with less maintenance and fewer repair costs

Optical dissolved oxygen sensors do cost more up front (more on that later). However, over the course of its lifetime, optical sensors should accrue far less maintenance costs, both in parts and labor.

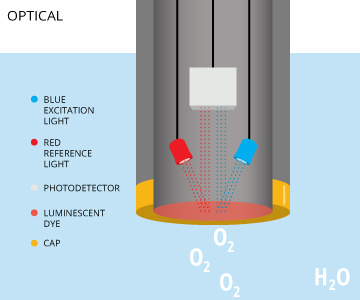

Some sources say that because the sensor cap of an optical sensor is more robust, it needs replacing only every 12 months as opposed to 6 months or more often for electrochemical sensors. And, because there are no anodes to replace, like in some electrochemical sensors, maintenance is a snap. It’s as simple as removing one sensor cap and replacing it with another.

Usually, maintenance for optical sensors require only rinsing and wiping off the sensor. Electrochemical sensors often require multiple steps of disassembly and cleaning.

Optical dissolved oxygen sensors are reliable, long term options for DO monitoring. (Credit: Fondriest Environmental)

Pro: More accurate DO measurements over time

Optical and electrochemical dissolved oxygen sensors can both be highly accurate, especially right after you’ve calibrated them. But optical sensors experience less drift than electrochemical ones (also called Clark cells). Drift means that, over time, dissolved oxygen sensors can become less accurate until they are calibrated again. The United States Geological Survey put it this way in their review of the technology:

“The results of this comparison study indicate that the optical sensors had accuracies similar to those of the Clark cells but were less prone to decreasing accuracy over time caused by fouling and calibration drift.”

They also found that optical sensors had no missing data over a test period, while electrochemical sensors failed to record values from time to time.

Optical sensors are also more accurate over a range of conditions. Some dissolved oxygen sensors require water to flow past them. Because they use up dissolved oxygen as they measure it, if new water doesn’t flow past the sensors, readings will be artificially slow. Optical sensors, on the other hand, are non-consumptive. This means that they don’t use up dissolved oxygen as they measure it. As a result, optical sensors will provide more accurate dissolved oxygen measurements in water with little movement, deep water or small volumes of water.

Con: More expensive than other dissolved oxygen sensors

All the advantages listed above come at a cost. Optical sensors are more expensive up front than electrochemical ones. After the initial purchase, optical sensors are likely to cost less by reducing maintenance labor and requiring fewer replacement parts, but the initial cost can be hundreds of dollars more. The cost difference between electrochemical and optical sensors only grows when buying multiple sensors is required.

There are a few other minor drawbacks to optical sensors, but they are usually mirrored by a similar drawback on the part of electrochemical ones. There is a list of chemicals and substances that interferes with the functioning of optical sensors, but a list that’s at least as long applies to electrochemical ones as well.

Despite the cost, optical sensors offer flexibility. They don’t require constant monitoring or maintenance. Depending on your dissolved oxygen monitoring needs, budget and availability of labor, an optical sensor might be the right choice for you.

0 comments